We are committed to excellent and outstanding service

Gers Plastics and Rubber Machinery (GPRM) is a well-established supplier of imported machinery for the plastics and rubber industries in Southern Africa. Founded in 1996 and based in Pretoria, we offer a wide range of machinery including plastics extrusion, recycling, compounding, pelletizing, milling, and testing. We also supply rubber compression and extrusion machinery. We represent top global brands and provide excellent service and aftercare for machines, spare parts, and electrical work.

We provide the know-how and equipment to process any polymeric materials.

A passion for helping our customers

Our comprehensive suite of professional services caters to a diverse clientele, ranging from educational institutions to multinational corporates.

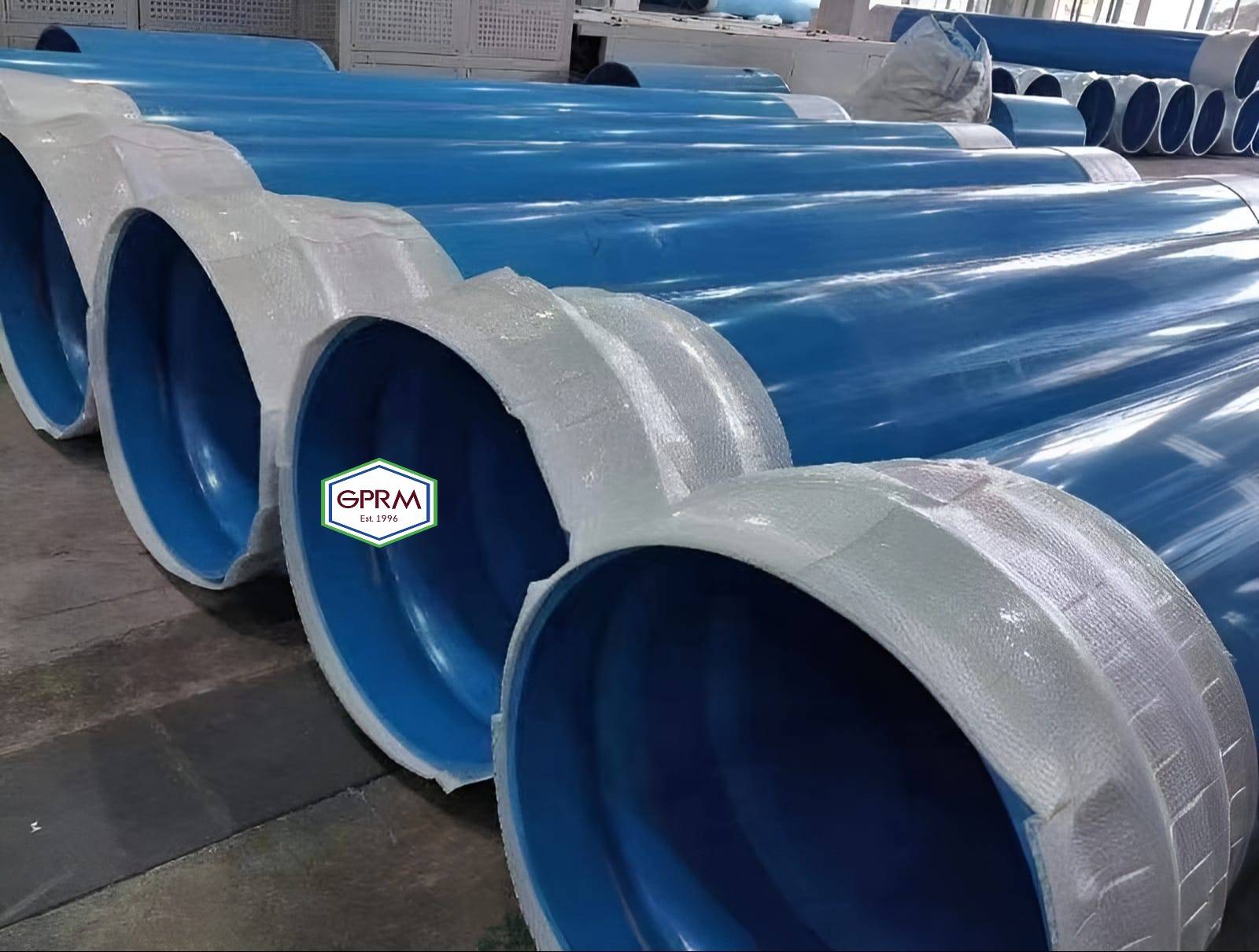

Extrusion

In extrusion, material costs dominate (up to 80% of operating costs). To minimize expenses, prioritize machines with low energy consumption per kg, as they can offset higher upfront costs through reduced electricity costs and increased output.

Large material savings result from precision extrusion using loss in weight feeders.

Sagging is prevented by internal cooling which is possible when swarfless cutters are used.

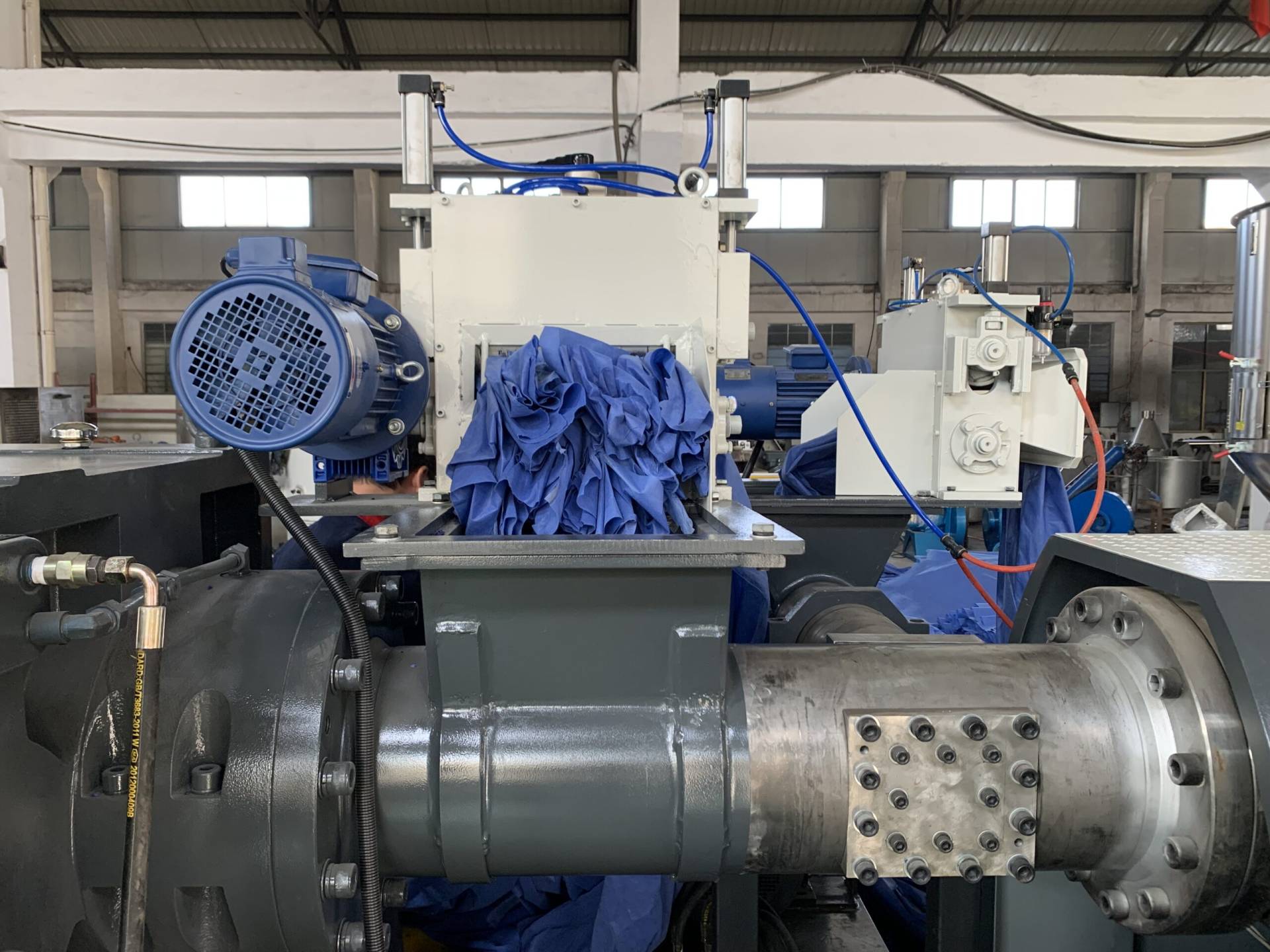

Recycling

Maximize recycling efficiency with our large granulator, featuring quick-change blades that minimize downtime. Replace blades in just 20 minutes, compared to 4 hours with standard granulators, and significantly boost uptime and output.

Single rotor and two rotor shredders up to 2 meter width is part of our supply.

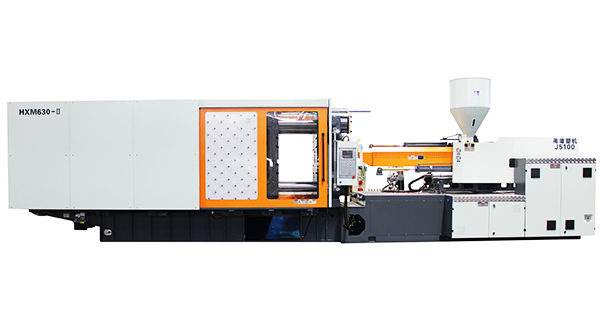

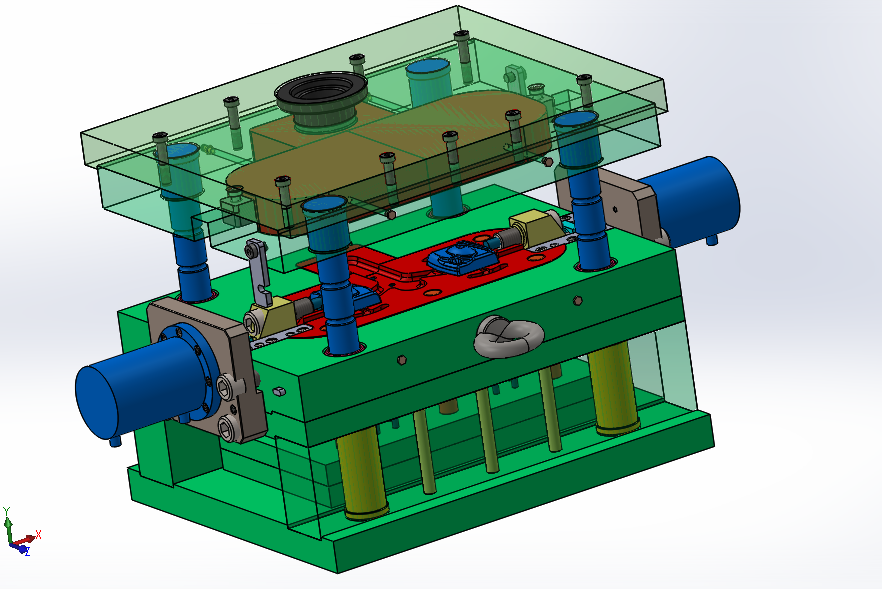

Injection Moulding

- Material selection and CAD product design.

Optimized mould design using Mould Flow analysis

- Energy-efficient Servo controlled machines (up to 60% savings on cycles over 30 seconds)

- Machine range: 80-2000 tons

- Comprehensive maintenance and troubleshooting services

Extrusion

- Single Screw: Helibar extruders from Extrudex offer exceptional energy efficiency (0.4-0.5 kWh/kg). Ideal for applications from grams/minute to tons/hour.

- Equipped with side feeders, vacuum venting, and continuous melt filtration

Counter-Rotating Twin Screw: Perfect for cost-effective, continuous UPVC and OPVC pipe extrusion.

- Co-Rotating Twin Screw: Versatile solutions for:

- Masterbatch production

- Highly filled compounds (up to 80%)

- Wide range of polymers and additives

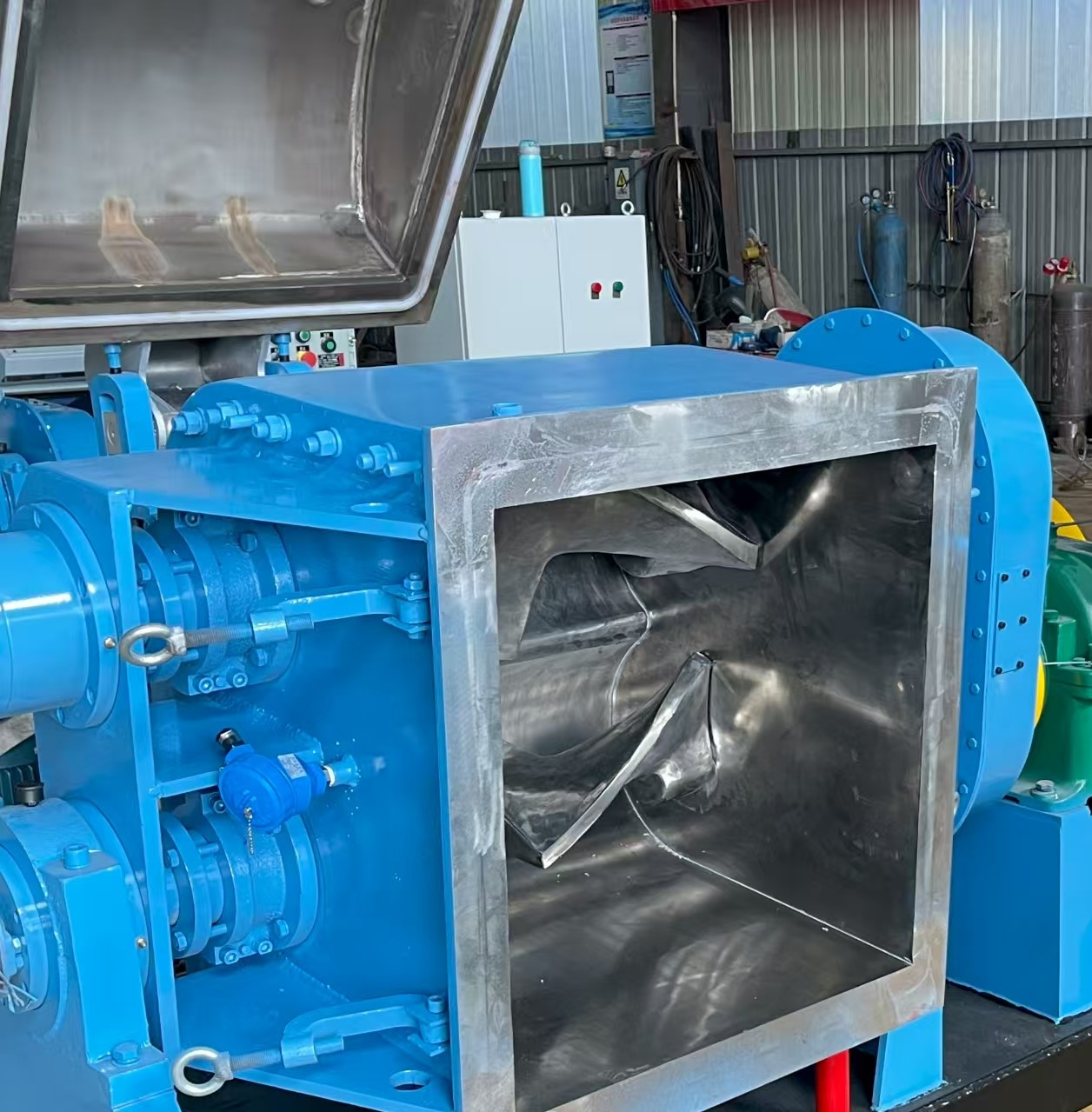

Mixing

- Rotary blade mixers for efficient blending

- Fountain mixers for gentle, thorough mixing

- High-speed mixers for dust-free operation and fast cycles (8-10 minutes)

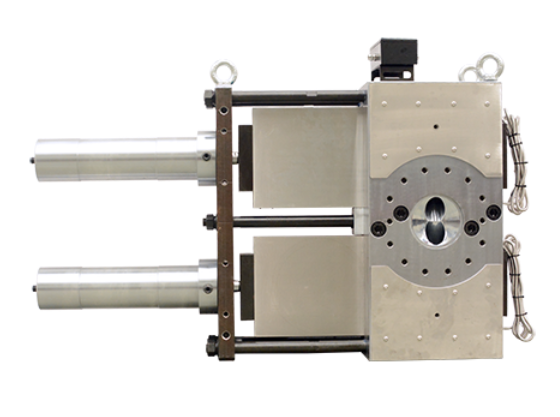

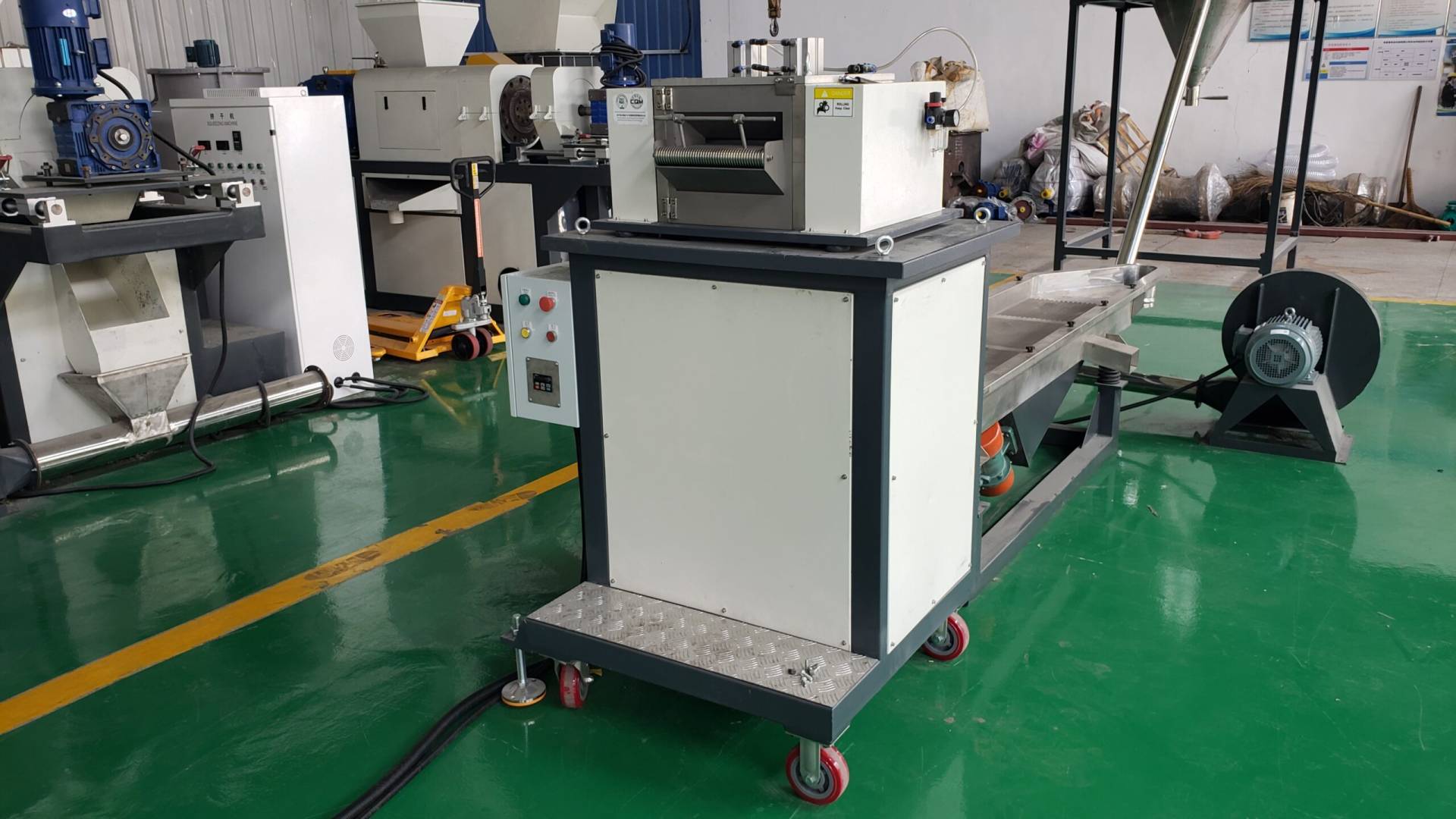

Pelletizing

- Strand pelletizing for efficient processing

- Water pelletizing for high-density materials (>1 g/cm³)

- Advanced pelletizing technologies:

- Water ring

- Underwater

An array of resources

Our comprehensive suite of professional services caters to a diverse clientele, ranging from small businesses to multinational enterprises.

Complete installation and commissioning

- Ensuring site readiness

- Procuring and inspecting equipment

- Training personnel for installation and operation tasks

Electrical and electronic repair and support

- Diagnostic and Repair Services

- Preventative Maintenance

- Emergency Support Services

CAD Design and Reverse Engineering

- Building accurate virtual models from initial concepts or blueprints.

- Employing 3D scanners, Coordinate Measuring Machines (CMMs), or other tools to capture physical dimensions and geometries.

“Gers Plastics and Rubber has previously supplied entities of the Barnes Group with machinery of a very high quality. We were (and still are) extremely satisfied with their efficiency of supply as well as their aftercare services.”

Doron Barnes

CEO of Barnes Group

Watch, Read, Listen

- Extrusion (7)

- Granulators (2)

- Injection Moulding (1)

- Piping (2)

- Plastics Education (2)

- Recycling (2)

Join 900+ subscribers

Stay in the loop with everything you need to know.